CIGÉO: IRSN delivers its 1st opinion on the project construction licence application

On April 24 and 25, 2024, IRSN presented to the Advisory Committee of Experts on Waste (GPD) the conclusions of its technical review of the basic data used to assess the safety of the Cigéo project, a deep geological repository for radioactive waste. This technical review is part of the examination of the construction licence application for the Cigéo project submitted in 2023 by the French national radioactive waste management agency (Andra).

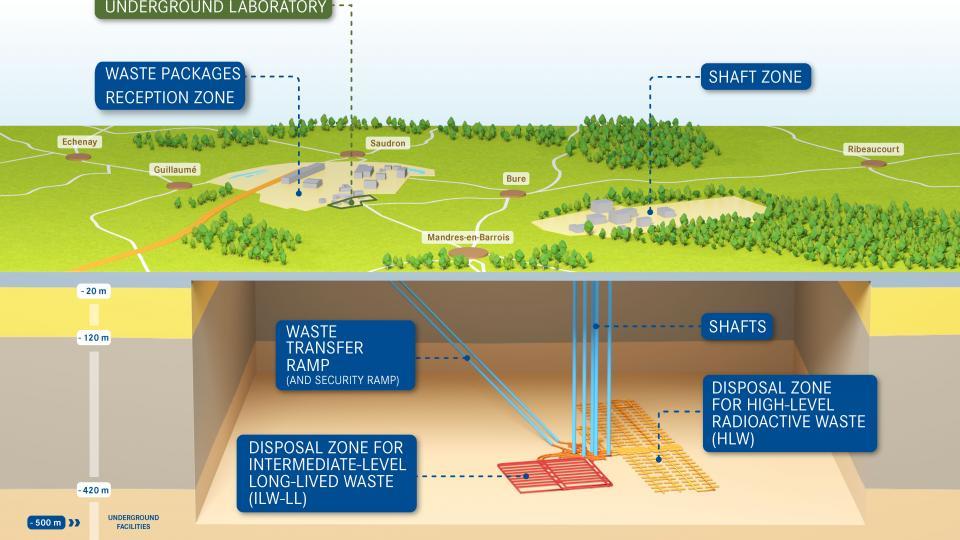

Cigéo is the French project for the reversible deep geological disposal of high-level (HLW) and long-lived intermediate-level radioactive waste (ILW-LL). Located on the border between the Meuse and Haute-Marne regions of France, Cigéo is designed to dispose of this waste 500 meters below the surface in a layer of clay rock. The construction license application is a major milestone in the creation of Cigéo.

IRSN's review of the construction license application for the Cigéo project is organised over a period of 30 months into three thematic groups:

- basic data used for the Cigéo safety assessment (GP1),

- safety assessment related to the operational phase (GP2),

- safety assessment related to the post-closure phase (GP3).

IRSN has just finalised the first part, i.e. GP1.

This work follows on from previous opinions and reports issued by the Institute at the request of the French Nuclear Safety Authority (ASN). One example is the safety options report reviewed in 2017.

The aim was to examine the knowledge compiled and the assumptions used by Andra for the Cigéo safety demonstration in relation to the inventories of waste packages, to the site and the host-rock chosen for the Cigéo facility, as well as to the engineered components of the disposal system and their evolution over time. Particular attention has been paid to the data acquisition methodology, the adequacy of data with regard to the models used, and the estimation of the uncertainties considered at this stage.

IRSN's technical review was based in particular on the experimental research and modelling programs it conducts, notably in its underground laboratory at Tournemire (Aveyron).

Conclusions of IRSN's assessment

IRSN considers that the knowledge developed by Andra in the areas of waste packages, Meuse/Haute-Marne site, Callovo-Oxfordian formation and cementitious materials is based on sufficient data for the safety assessment of Cigéo at the construction licence application stage. This knowledge is based on detailed hydrogeological and geotechnical characterisations, an appropriate assessment of meteorological hazards and an adequate understanding of the properties of the host rock, cementitious materials and waste packages, as well as their evolution under the effect of transient thermal, water, mechanical and chemical disturbances.

Regarding the reference and reserve inventories, the data collected by Andra is generally relevant, both for the Cigéo safety demonstration and for the adaptability studies considering the chosen prospective industrial scenarios. Some uncertainties remain, however, including uncertainties relating to the reference inventory that may impact the number of disposal cells and the disposal chronologies; these will have to be addressed through the flexibility of Cigéo while in operation. In addition, considering the possibility of a future fleet (eight additional EPR 2, SMR, RNR, etc.), the capacity of the facility to dispose of more waste will have to be assessed on the basis of further adaptability studies, considering time horizons that can be defined once the decisions relating to the future fleet have been taken.

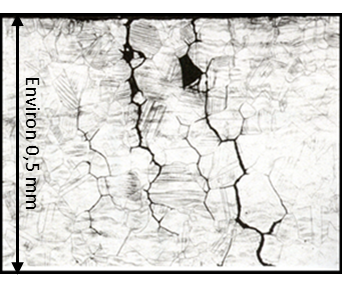

At this stage of the construction licence application review (GP1), IRSN has identified two topics that require particular attention, respectively relating to HLW cells and to sealing structures, which refer to the pilot phase. Regarding HLW cells, it is important to provide the supporting evidence for the design basis of metal components before the first HLW cell is excavated, and to resolve the uncertainty regarding the possibility of flexures affecting the host rock at the location of the future HLW disposal zone. For sealing structures, which are still at the stage of design principles , efforts must be made to minimise damage to the rock while excavating the facility's shafts in areas that are subsequently to be sealed. Particular attention must also be paid to the definition of these structures and the in situ demonstration of their operability.

The present review will be supplemented by the Cigéo operational and post-closure safety demonstration reviews, carried out for the GP2 and GP3 technical reviews respectively and currently underway.

Involvement of civil society in the Cigéo assessment process

In addition to its assessment of Andra's construction licence application, IRSN established a technical dialogue with the National Association of Local Information Committees and Commissions (Association nationale des comités et commissions locales d’information - ANCCLI), and the Local Committee for Information and Follow-up of the Bure Laboratory (Comité local d’information et de suivi du laboratoire de Bure - CLIS de Bure). This dialogue is a continuation of the initiatives of openness to civil society on HL and IL-LL waste carried out since 2012.

It was conducted in the form of plenary meetings and thematic workshops with the dual aim of taking the concerns of civil society into consideration in order to make IRSN's review more robust, and of allowing civil society to form its own opinion and therefore to participate in the process leading up to the public decision.

The main subjects of interest to participants in connection with GP1 assessment were the so-called "reference" and "reserve" waste inventories, the site characteristics (in particular the evolution of faults, water circulation, the potential geothermal resource, the properties of the host layer), and the pilot phase.

Download :

Note: The English version of IRSN's opinion is provided for information only. Only the original document in French is authoritative.