PROGRES project

Launched in 2007, the aim of the Progres (formerly Pearl) research programme is to gain a better understanding of the phenomena involved in the flow of water and steam within a porous medium made up of solid particles at very high temperatures under conditions representative of a core meltdown accident (or severe accident). It involves the Prelude and Pearl installations on IRSN's Thema platform.

Project characteristics

Completion dates : 2007 to 2019

Pilote : IRSN

Budget : IRSN, EDF, European Commission

Partner : EDF

Download the programme presentation sheet (FR)

Project Background

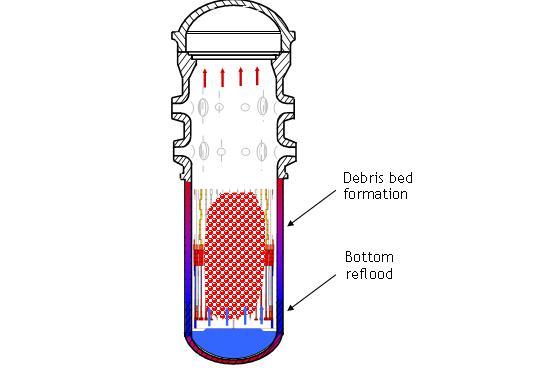

In the event of an accidental and prolonged loss of cooling, the fuel rods making up the core of a pressurised water nuclear reactor (PWR) will be damaged, and a large proportion of them will collapse, forming what is known as a ‘debris bed’. This is in fact a mass of fragments from the zircalloy cladding and the UO2 pellets (or, in the case of MOX fuel, UO2 and PuO2 pellets) they contain. This problem was highlighted in the analysis of the Three Mile Island accident in the United States in 1979.

To try to prevent such an accident, one of the recommended operations is to reinject water into the core, an action known as ‘reflooding’. Although this operation is essential for cooling the fuel, it can also endanger the integrity of the reactor containment. Injecting water into a core at a very high temperature can lead to an explosive thermal interaction, known as a ‘steam explosion’, between the water and the molten core, if the core has begun to melt.

Programme principle

During the reflooding of a degraded core, the injected water flows through a mass of particles (or debris bed) at very high temperature, the geometry and porosity of which vary locally. This debris bed can be difficult to cool because the water can bypass the least porous areas of the bed (which are also the hottest areas) in favour of the more porous areas.

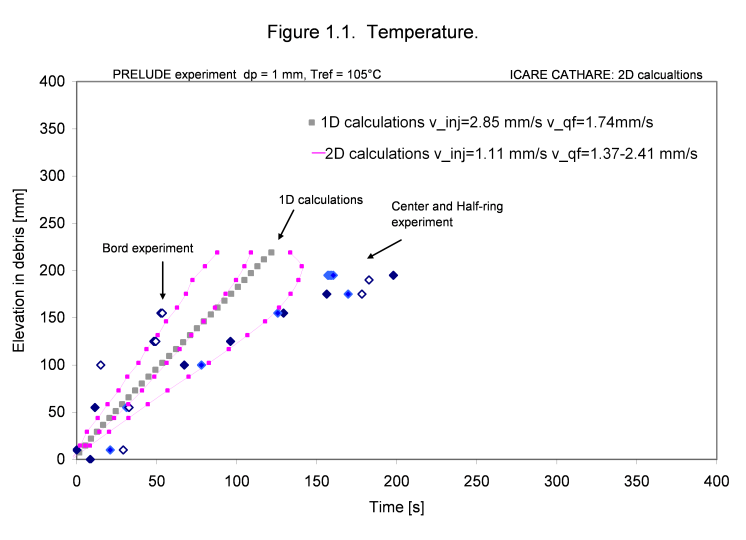

To predict the progression of water within the debris bed and the resulting steam production, it was necessary to develop detailed thermal-hydraulic models, describing the damaged core as a porous medium with variable geometry and characteristics. These models were developed using Icare-Cathare software, which simulates the degradation of a reactor core.

After validation on experimental data acquired on the Prelude and Pearl facilities, these models will be simplified and then introduced into the Astec software package, which simulates all the phenomena that can occur in a nuclear reactor during a severe accident.

The Progres programme involves refurbishing clusters of metal particles, heated to a high temperature (1000°C), and whose size and spatial distribution are representative of those expected in a pressurised water reactor. The particles used, ranging from 1 to 8 mm in diameter, are made of steel. They are placed in a quartz cylinder surrounded by a solenoid that heats them by induction to simulate the residual power of the core debris. As soon as the set temperature is reached, ‘reflooding’ is triggered by injecting water at the base of the cylinder. Instrumentation placed in the debris bed is used to characterise the progression of the water in the porous medium, the production of steam and the resulting rise in pressure, as a function of parameters such as the water injection rate, the size of the particles, the power deposited in the bed and the pressure.

Programme schedule

The programme has two stages

The first stage took place on the Prelude device, which is a reduced-scale model of the Pearl installation. The test sections vary in diameter from 110 to 290 mm and contain between 5 and 60 kg of particles. This set-up was used to validate the technological options for the Pearl installation, in particular to carry out feasibility studies on induction heating and qualification tests on the instrumentation. The first tests of the experimental programme, which took place from 2010 to 2012 on this device, enabled the simulation tools to be improved and validated.

Results obtained between 2010 and 2012

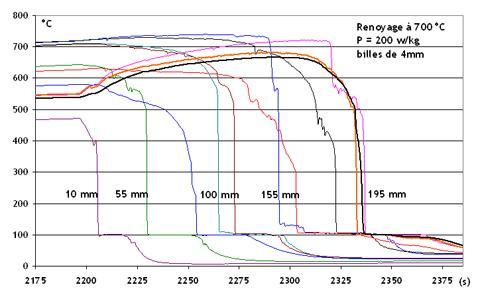

The experimental campaigns carried out between 2010 and 2012 on the Prelude device demonstrated the feasibility of reflooding a bed of balls heated to 900°C, while maintaining a power deposit of 200 W/kg in the bed during water injection. Thermocouples implanted in the bed at different levels (see figure) make it possible to follow the progression of the quenching front, i.e. the boundary separating the zone where the balls have been cooled (at the bottom) from the zone where the balls are still hot and where intense boiling occurs. We were also able to measure the pressure within the bed of balls and the flow of steam produced.

In addition to the tests to qualify the techniques to be used in Pearl, several campaigns, representing more than a hundred tests, were carried out in Prelude, with the aim of providing useful results for understanding the physical phenomena at play during reflooding and improving the correlations currently used in the Icare/Cathare and Astec simulation software.

We were thus able to estimate the maximum heat flux extracted from the balls by the water as a function of their temperature. We also determined the rate of progression of the quenching front as a function of injection speed, initial temperature and bead size.

comparison of the speed of progression of the quenching front measured with that calculated, at different radial positions of the bed of balls. ©IRSN

By measuring the flow of steam produced, it was possible to assess the cooling efficiency for different flooding conditions. Finally, it was found that, under certain conditions, some of the balls can be lifted by the steam travelling at very high speed through the upper part of the bed. This phenomenon, known as ‘fluidisation’, is conducive to efficient cooling.

The 2012 test campaigns involved a bed of balls surrounded by a zone of greater porosity where water can flow more easily. This situation is more representative of the ‘reactor’ situation because a damaged core presents significant heterogeneities and the progression of the water first takes place via the paths offering the least resistance. We can therefore assess the impact of this bypass on the cooling of the bed of balls it surrounds.

Test campaigns at the Pearl facility

The Pearl facility is unique in the world in terms of its size and variations in parameters. It simulates the core of a reactor on a ¼ scale.

The diameter of the test section (5 times larger than that of Prelude) will enable better analysis of the two-dimensional effects on water and vapour flows, induced by the presence of a bypass at the periphery of the particle bed. In addition, the tests will be carried out at pressures of up to 10 bar, which was not possible with Prelude.

The sizing of the Pearl installation will make it possible to study the effects of the injected water flow rate (2 to 50 m3/h), the system pressure (1 to 10 bar), the initial temperature of the debris bed (400 to 900°C), the undersaturation of the injected water and the heating (0 to 300 W/kg, simulating the residual power of the core) on reflooding. The debris bed can be made up of balls of identical size (homogeneous bed) or a heterogeneous debris bed with balls of variable size, heated (metal balls) or unheated (quartz balls).

Four test campaigns are planned, some of which will involve the Prelude installation:

- Campaign 1 (2014-2015) : Reflooding of the homogeneous debris bed (particles of the same size) - study parameters: flow rate, pressure and temperature

- Campaign 2 (2016) : Effect of the geometric characteristics of the debris bed - study parameters: particle diameter distribution and bypass size

- Campaign 3 (2017) : Study of a compact zone in a debris bed Campaign 4 (2018) : Study of the effect of oxidation of metallic materials and hydrogen production

Equipment & technology

- Pearl installation

- Icare-Cathare calculation code

- Astec software system

IRSN's laboratories involved

- The laboratory for experiments in mechanics and materials (LE2M)

- The laboratory for the study of corium physics (LEPC)