CIP Program CABRI

Created in 2000, the objective of the Cabri International Program (CIP) is to study the behavior of nuclear fuel rods and cladding during a reactivity-injection accident (RIA) in a pressurized water reactor (PWR).

The program and its partners

The Cabri international program started in 2000 to study the behavior of nuclear fuel rods, their cladding in particular, during a reactivity-injection accident (RIA) in pressurized water reactor. It is part of a set of programs led by IRSN on nuclear fuel behavior.

Under the auspices of the OECD Nuclear Energy Agency, this program overseen and cofunded by IRSN brings together partners from France (EDF and CEA) and twelve foreign countries (Czech Republic, Finland, France, Germany, Japan, Slovakia, South Korea, Spain, Sweden, Switzerland, United Kingdom and the United States) representing safety authorities, nuclear licensees and research laboratories.

The objectives

A reactivity-injection accident (RIA) includes a rapid, sudden and local rise in neutron flux, which results in an increase in nuclear power due to fission and causing fuel temperature to rise rapidly.

Two types of cladding failure can occur during an RIA:

- pellet-cladding mechanical interaction (PCMI) phase, when the cladding is still cold and the fuel expands significantly, resulting in high mechanical stress on the cladding;

- failure due to excessive deformation during the post-departure from nucleate boiling (DNB) phase, when the cladding has resisted the PCMI phase and significant cladding deformation (ballooning) occurs due to the degradation of the cladding-coolant heat exchange coefficient and a rapid rise in cladding temperature.

Since the first failure mode does not depend on coolant conditions, it can be studied in thermal hydraulic conditions that are not representative of a PWR. The second failure mode depends heavily on thermal hydraulic conditions and can only be studied experimentally in PWR conditions. This constitutes the major challenge of the CIP.

The objectives of the CIP include:

- understand fuel rod behavior in an RIA situation, particularly in the event of cladding dryout or cladding failure during the transient;provide quantitative information for the development and validation of simulation tools (including IRSN’s SCANAIR software);

- study the behavior during a RIA of new types of cladding and fuel that offer improvements in other situations.

The program may also provide information to confirm certain new safety criteria defined by EDF for the short term phase of the rod ejection accident and which were addressed in an investigation by IRSN presented to the Advisory Committee for Nuclear Reactor Safety in June 2017.

The tests

CIP includes a total of twelve tests. The first two reactivity injection tests on irradiated fuel rods were performed in 2002 in the Cabri reactor equipped with a "sodium loop", i.e., in which the coolant is liquid sodium. The loop represents the reactor coolant system in which the reactor coolant circulates. The two tests provided an opportunity to study phenomena that do not depend on the nature of this coolant (PCMI phase).

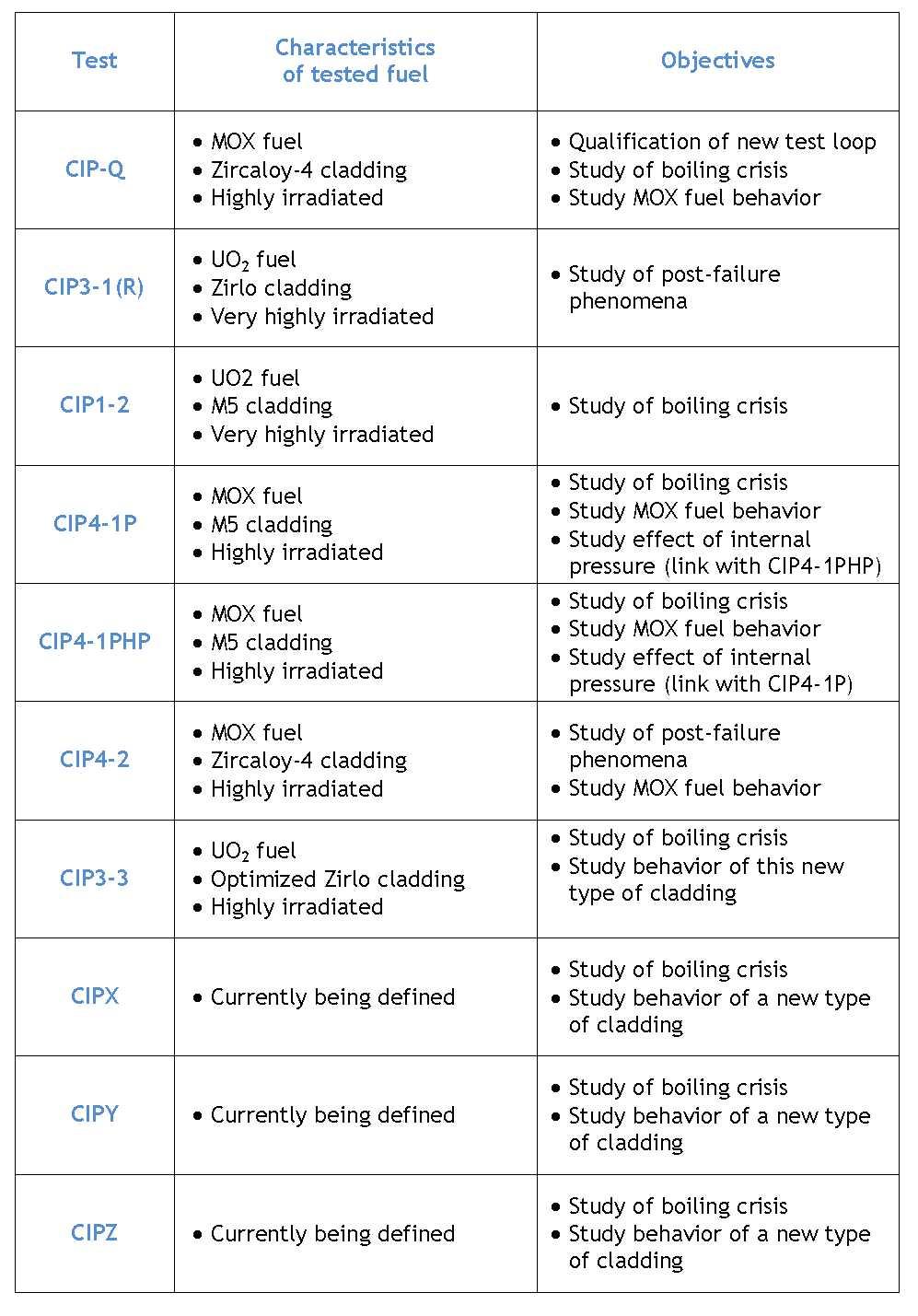

However, to study accident conditions in a PWR (phase post-DNB and fuel-coolant interaction in the event of cladding failure), the "sodium loop" had to be replaced by a pressurized water loop. The renovation of the reactor core cooling system, as well as the remediation work to bring the facility into compliance, have been completed. The following ten tests in the program consist in exposing the sections of irradiated fuel to conditions found during a reactivity injection accident. The following table lists the characteristics of the fuels that will be tested and the main objectives of each of the tests

Table of the CIP program tests

The first test, called CIP-Q, has been successfully performed on the 16th April 2018. See the press release on the IRSN website and the CEA website

Characteristics

Tests characteristics

- Primary reactor power: 100kW ;

- Power transient duration: 10 à 100 ms ;

- Maximum transient power: about 20 GW ;

- Injected energy: till 200 MJ.

Water loop characteristics:

- 280 °C, 155 bar, flow rate till 6 m3/h